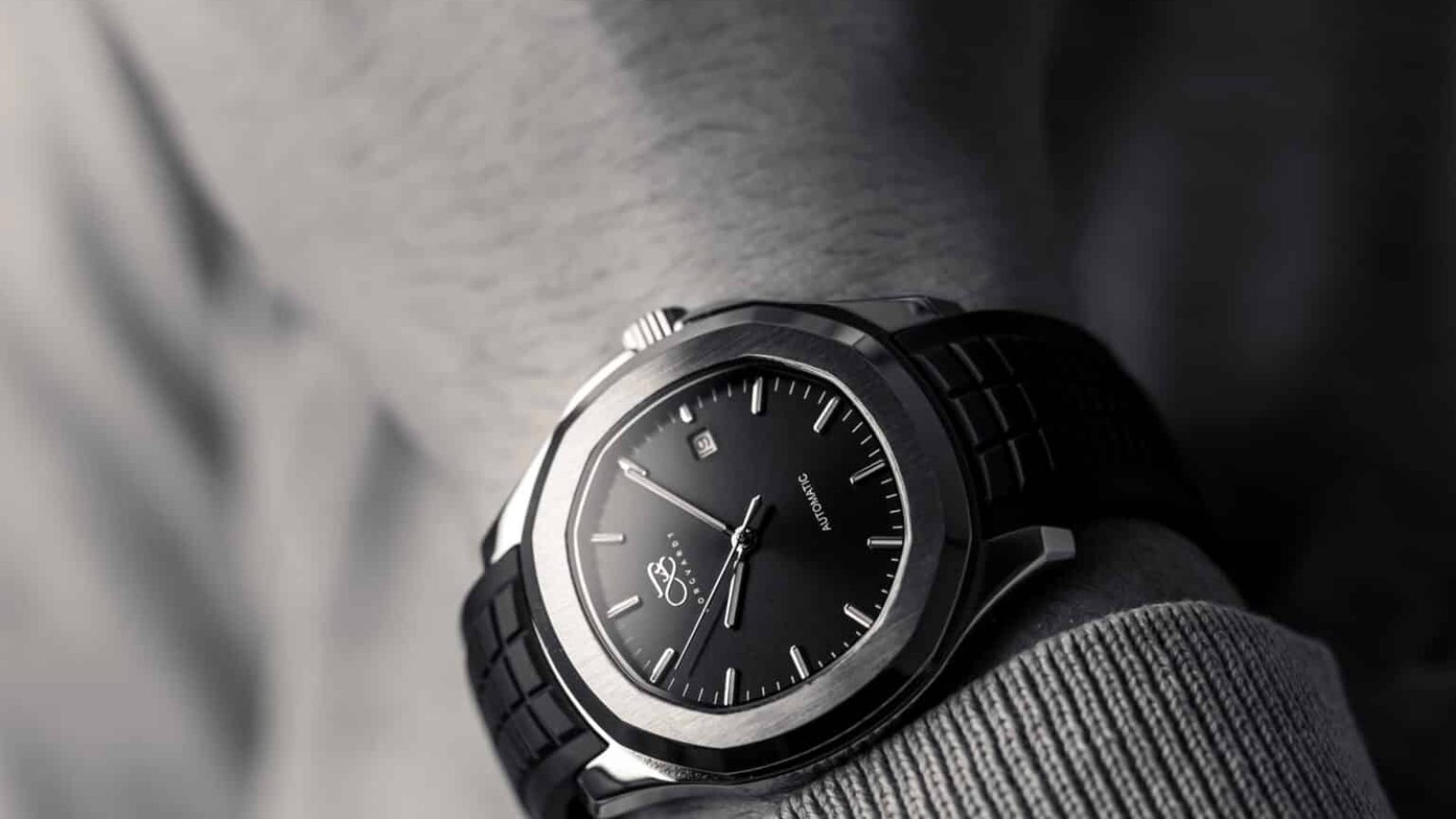

Every Borgvardt watch starts with a conscious design choice, is assembled from thoroughly tested components from specialist suppliers, and is finished and prepared in Esbjerg before being shipped onward.

Conscious choices and composition

The design process at Borgvardt is not about inventing everything from scratch. It is about composition and balance.

When a Borgvardt watch is created, the process begins with inspiration from classic mechanical watches from the 1970s. This is where proportions, function, and aesthetics form the basis. There are clear and distinct references to a time when watches were designed with a clear purpose.

Instead of designing each component from scratch, I work with tried-and-tested components from specialist suppliers, each of whom has extensive experience in their field. This allows me to focus on what is most important to me: the big picture.

A Borgvardt watch is created through the combination of:

Watch case

Dial

Gauges

Mechanical clockwork

Chain or strap

Each component is selected individually, and nothing is left to chance. Proportions, surfaces, colors, and function must work together before a design makes sense. It is in the composition that the watch acquires its character.

I work exclusively with reliable suppliers and materials known for their quality and durability—including 316L stainless steel, sapphire crystal, and mechanical movements that have proven their reliability over time. This provides a solid foundation for creating a watch that can be worn every day and will last for many years.

For me, design is not a question of being able to say “in-house.” It is a question of taking responsibility for the choices that are made. A Borgvardt watch is therefore the result of conscious curation, not mass production or fast trends.

The design process is only complete when all components function as a single entity, both visually and functionally. Only then does it make sense to send the watch on to Esbjerg for assembly and preparation.

When you buy a Borgvardt watch, you don't just get a mechanical watch—you get a piece of craftsmanship that I have personally handled. Although I don't produce the components myself, I select suppliers with extremely high standards in terms of movements, steel, sapphire crystal, and finish.

Selection before assembly in Esbjerg

Every Borgvardt watch begins with selection.

I work exclusively with suppliers who specialize in modern watch production and who supply components that have already been tested and checked according to fixed tolerances.

This applies to:

Mechanical clockworks

Watch cases in 316L stainless steel

Sapphire glass

Dials and hands

Chains and straps

All parts undergo quality control at the manufacturer before being shipped. Only components that meet requirements for fit, finish, and function become part of a Borgvardt watch.

Assembly and inspection in Esbjerg (in person)

When the components arrive in Esbjerg, the part of the process that I am responsible for begins.

Each watch is assembled and prepared individually. This is where the whole is formed, and where small adjustments make a big difference. During assembly, I review, among other things:

Checking the mechanical movement's accuracy and stability

Adjustment and correct alignment of hands

Fit between case, back case, and sapphire crystal

Fitting and checking chains or straps

Visual inspection of the surface finish of the steel

Water resistance testing (depending on model and specification)

It is not a process that can be rushed. A mechanical watch must feel right, not just function technically.

Mechanical responsibility

For me, quality isn't just about materials and specifications. It's about responsibility.

A mechanical watch is a living object. It will age, be used, and develop patina. That is precisely why it is crucial that the foundation is sound from the outset.

When you wear a Borgvardt watch, you are wearing a watch that is:

Chosen with care

Assembled with calm

Controlled with responsibility

That's how I think mechanical watches should be built.

Slowly. Consciously. And to last – both today and for many years to come.